of GALvanized FANtastic steel products,

as a superior alternative to Conventional

hot-dipped zinc coatings for extrordinary

applications, worldwide.

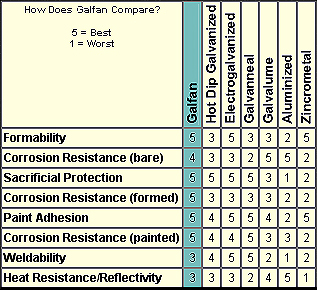

In October 2000, the ownership rights to Galfan® Estate and Technology were transferred to the Galfan Technology Centre Inc. While the growth, in the use of hot-dip galvanizing using virtually pure zinc has been dramatic, and the related decline of electro-galvanizing is a well known trend, the fortunes of another long-established and important anti-corrosion coating – Galfan® – are less well known. Nevertheless, over 3 million MT of Galfan®-coated steel was produced in 2011, but due to new new technological process development and innovative marketing strategies, its global popularity is dramatically increasing. Galfan® as a trademark has been around since the International Lead Zinc Research Organization (ILZRO) obtained worldwide patents on this new alloy for anti-corrosion coating in 1981. This grew from an ILZRO-organized project co-sponsored by Arbed, Cockerill Sambre, Usinor and Sacilor (and now all part of Arcelor), British Steel, Fabrique de Fer de Maubeuge (now all part of Corus), New Zealand Steel, and Stelco (Canada) at Centre de Recherches Metallurgiques in Belgium. This project showed that an alloy combining 95% zinc, nearly 5% aluminum plus specific quantities of rare earth mischmetal could be reliably used in the hot-dip coating process, and conferred substantially improved performance to the end-product. Licenses to use the revolutionary Galfan® technology were granted to manufacturers worldwide. The name Galfan® was given to the new alloy product during a business meeting one evening after the first large-scale production campaign at Sacilor’s, Ziegler S.A. works in Mouzon, France on July 8-10, 1981. Upon reviewing the success of this campaign, in which 150 tonnes of coils were coated, with high quality product obtained after running the first 250 meters of strip through the mill, J-L. Pagniez, head of the French Coated Steel Information Center (CITAG), christened the product "galvanisation fantastique". This was shortened to Galfan®, and this name then trademarked Today our Licensee’s, are a select group of producers, Certified by GTC, committed to specializing in the production of Galfan coated steel, that meets the Worldwide Performance that has been established in the International Market Place.

GalfanŽ-coated sheet, wire and

tube steel has found its way into a wide variety of products for the construction,

automotive, electrical appliance, industrial and farming sectors (see applications). GTC supports its network of

"premier producer licensees", to which it supplies technical support and updates

on new products and application developments and a continuing research and development

program. GTC is funded through royalties on tons of GalfanŽ coated steel produced by the

licensees.

|

Phone: (330) 453-9136 Fax: (330) 453-6006